Startup DACLab Aims to Reduce Costs of Carbon Capture to $250 per Ton, Cutting Through Empty Promises in the Direct Air Capture Industry

The global emissions reached an all-time high last year, despite international commitments to reduce carbon pollution. To combat this issue, the focus has shifted towards direct air capture (DAC) of carbon dioxide (CO2). However, the energy-intensive nature of DAC has deterred widespread adoption due to its high cost.

One startup, DACLab, claims to have found a solution to lower the energy consumption required for DAC. Aditya Bhandari, co-founder and CEO of DACLab, revealed that their method only requires 1,500 kilowatt hours (kWh) per metric ton of CO2, compared to the estimated 2,000 kWh when the technology is optimized and scaled up.

Operating in stealth mode for the past four years, DACLab recently secured $3 million in seed funding. The round was led by early Discord investor Peter Relan, with additional investments from Silver Lake co-founder Dave Roux, WovenEarth Ventures founder Jane Woodward, and others.

Most direct air capture systems involve blowing air over a solid material that absorbs CO2. As the material becomes saturated, the absorbed CO2 needs to be released and stored elsewhere, which is an energy-intensive process often requiring temperatures between 80°C and 120°C. Liquid sorbents require even higher temperatures.

To minimize costs, many startups combine the capture and release processes in a single unit. DACLab separates these two steps, capturing CO2 in one location and releasing it in another. The process involves relatively low heat for a solid sorbent, around 70°C, according to Bhandari.

This bifurcated setup is typically found at industrial sites with concentrated exhaust streams. DACLab’s technology was repurposed from such industrial designs. Another startup, Global Thermostat (recently sold for parts), also used a split design.

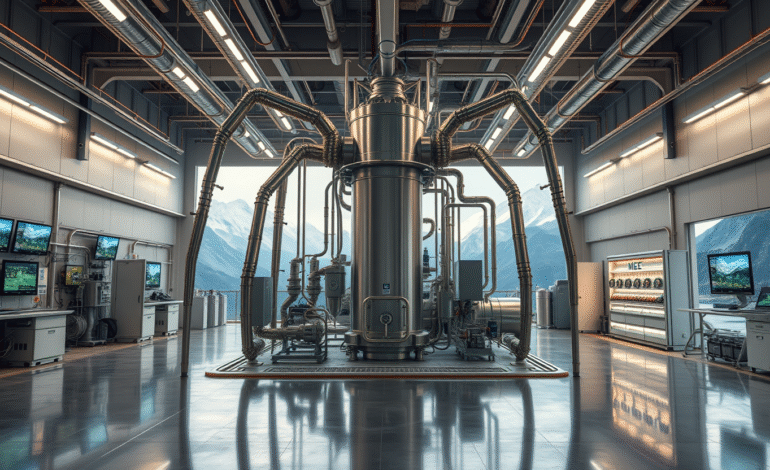

DACLab’s technology originates from TU Wein in Austria, where a partnership with Shell produced a point-source carbon capture unit that operated for nearly three years. Bhandari noted that this was the largest carbon capture facility in Austria at the time.

The startup has developed two units capable of capturing 100 metric tons per year, and plans to build larger versions capturing 1,000 and 5,000 metric tons per year. The smaller unit will be deployed in Washington State, while the larger one is planned for installation in Kenya.

DACLab sells its 100-metric ton unit for under $500,000. In the future, they aim to supply units to oil and gas companies, carbon project developers, and companies manufacturing e-fuels for aircraft.

According to Bhandari, much of the cost of carbon capture will depend on its energy consumption. DACLab aims to further reduce consumption to less than 1,000 kWh per metric ton, which would enable them to capture CO2 for $250 per metric ton.

“We’re not going to be one of those direct air capture companies that promise you that we are going to reach $100 per [metric] ton today,” Bhandari stated. “Hopefully we can reboot this much-needed industry, because it is filled with a lot of, I would say, empty promises.”